Quality Testing Engines and Transmissions

By Ben Silver - April 22, 2015

By Ben Silver

In automotive recycling and selling used auto parts, engines and transmissions make up the bulk of our revenue stream. In fact, engines and transmission sales will account for 35%-50% of most salvage yards total parts sales. This makes proper inventory, testing, and quality control of these parts paramount.

The last thing you want to do, as an automotive recycler, is sell a bad mechanical part (engine, transmission, rear axle, carrier, etc.). The dealership or garage will have installed the product and then found the part to be defective. At Central Auto Parts, we do everything in our power to prevent this costly issue.

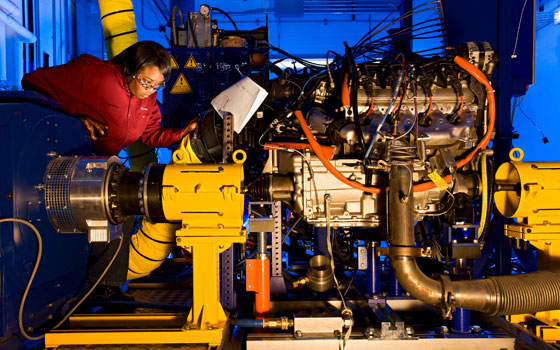

It all starts in our dismantling bay, with one of our trained, professional dismantlers. Regardless of the impact of the collision, our dismantlers are tasked with getting the engine to run. This is the most critical part of the testing. Obviously, if we can run the engine for a few minutes, listen for imperfections, and do a hot (while running) compression test, we know that the engine is good. This is the ideal scenario and what we are able to do with the vast majority of the vehicles we dismantle. There is the occasional “problem child” though. Generally, these vehicles have significant electrical damage that restricts our ability to run the engine or start the vehicle. Fortunately, we have method of testing these engines as well. This test is called a “Cold Compression” test. This test is accomplished by manually connecting the electrical starting components to an external power source. Once there is power we will manipulate the ignition sequence manually to produce compression in the valves. Our compression tester will tell us the condition of the valves and rings based on the amount of pressure is building up in the valves. It’s vitally important that every valve on the engine is tested, because one bad valve can mean a defective engine that needs repair. This is not as “pure” of a test of the engines condition as running it and “hot” compression testing the engine, but can tell us if the main functions of the engine are in good shape. A run test, compression test, or both are done on every engine that is sold by Central Auto Parts.

When we’re able to run the vehicle, we can test the transmission for defects as well. Unfortunately, the vehicles we process can very rarely be driven. So testing a transmission under load is very difficult to accomplish consistently. But with the vehicle running, we’ll test the transmission on the lift by running it through 1st & 2nd gear, as well as reverse. This tells us, at the very least, that transmission is transferring power from the engine to the axles. This is very important test that can be overlooked by some recyclers and is very important because transmissions tend to fail a slightly higher rate than engines. Once we have the transmission out of the vehicle, we remove the oil pan to look for any indication of an internal problem. The gears inside of a used transmission would have been working prior to the collision, and you can expect some metal shavings to be prevalent on the oil pans magnet. If there is an overwhelming amount of shavings and they tend to be pretty large (think larger than a pea), you may be dealing with a problem transmission that needs repair. We’ll also look out for oddities in the transmission fluid. Fluid that is too dark or odorous can indicate a problem as well.

Using these testing methods, we’re able to weed out a significant amount of used engines and used transmissions that may have otherwise caused a problem in the vehicle they set out to repair. When you’re looking for a used parts provider, consider their methods of testing and don’t be afraid to ask about the process. Also, make sure they have great warranty and reputation within the repair community. At Central, we provide a 90-Day Warranty on all of our mechanical parts as a standard. We also have available 1 Year/3 Year/Lifetime Parts and Labor Warranties available because we’re proud of our products and testing methods and aren’t afraid to cover them for the long haul.

Go Back In automotive recycling and selling used auto parts, engines and transmissions make up the bulk of our revenue stream. In fact, engines and transmission sales will account for 35%-50% of most salvage yards total parts sales. This makes proper inventory, testing, and quality control of these parts paramount.

The last thing you want to do, as an automotive recycler, is sell a bad mechanical part (engine, transmission, rear axle, carrier, etc.). The dealership or garage will have installed the product and then found the part to be defective. At Central Auto Parts, we do everything in our power to prevent this costly issue.

It all starts in our dismantling bay, with one of our trained, professional dismantlers. Regardless of the impact of the collision, our dismantlers are tasked with getting the engine to run. This is the most critical part of the testing. Obviously, if we can run the engine for a few minutes, listen for imperfections, and do a hot (while running) compression test, we know that the engine is good. This is the ideal scenario and what we are able to do with the vast majority of the vehicles we dismantle. There is the occasional “problem child” though. Generally, these vehicles have significant electrical damage that restricts our ability to run the engine or start the vehicle. Fortunately, we have method of testing these engines as well. This test is called a “Cold Compression” test. This test is accomplished by manually connecting the electrical starting components to an external power source. Once there is power we will manipulate the ignition sequence manually to produce compression in the valves. Our compression tester will tell us the condition of the valves and rings based on the amount of pressure is building up in the valves. It’s vitally important that every valve on the engine is tested, because one bad valve can mean a defective engine that needs repair. This is not as “pure” of a test of the engines condition as running it and “hot” compression testing the engine, but can tell us if the main functions of the engine are in good shape. A run test, compression test, or both are done on every engine that is sold by Central Auto Parts.

When we’re able to run the vehicle, we can test the transmission for defects as well. Unfortunately, the vehicles we process can very rarely be driven. So testing a transmission under load is very difficult to accomplish consistently. But with the vehicle running, we’ll test the transmission on the lift by running it through 1st & 2nd gear, as well as reverse. This tells us, at the very least, that transmission is transferring power from the engine to the axles. This is very important test that can be overlooked by some recyclers and is very important because transmissions tend to fail a slightly higher rate than engines. Once we have the transmission out of the vehicle, we remove the oil pan to look for any indication of an internal problem. The gears inside of a used transmission would have been working prior to the collision, and you can expect some metal shavings to be prevalent on the oil pans magnet. If there is an overwhelming amount of shavings and they tend to be pretty large (think larger than a pea), you may be dealing with a problem transmission that needs repair. We’ll also look out for oddities in the transmission fluid. Fluid that is too dark or odorous can indicate a problem as well.

Using these testing methods, we’re able to weed out a significant amount of used engines and used transmissions that may have otherwise caused a problem in the vehicle they set out to repair. When you’re looking for a used parts provider, consider their methods of testing and don’t be afraid to ask about the process. Also, make sure they have great warranty and reputation within the repair community. At Central, we provide a 90-Day Warranty on all of our mechanical parts as a standard. We also have available 1 Year/3 Year/Lifetime Parts and Labor Warranties available because we’re proud of our products and testing methods and aren’t afraid to cover them for the long haul.